TLDR

Whisky and Yeast

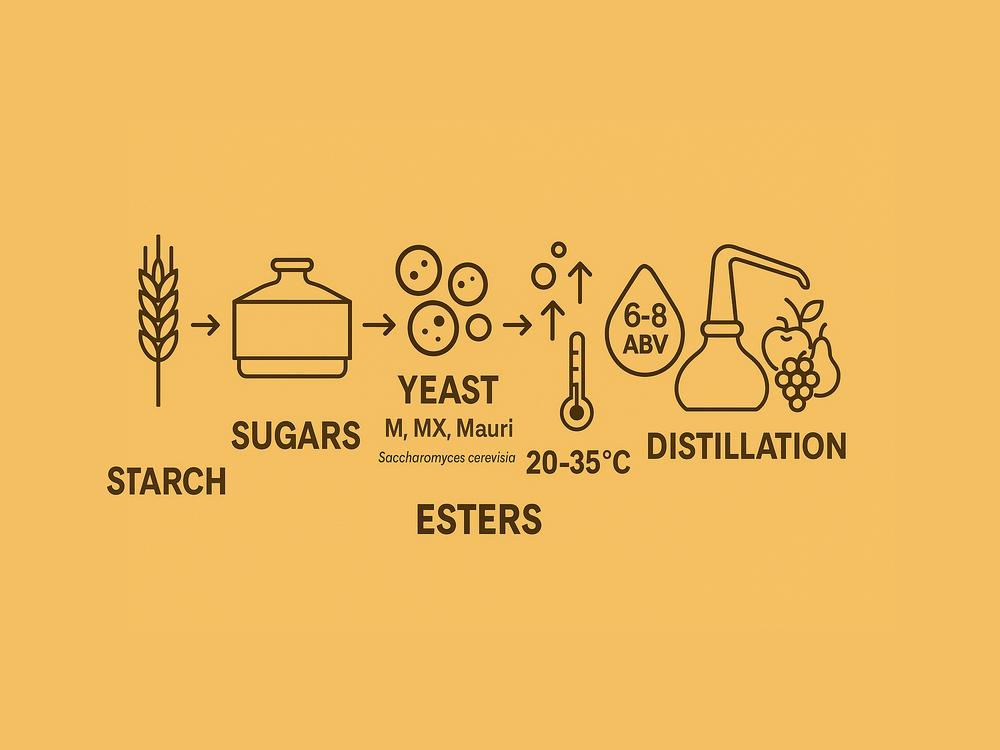

Whisky begins as beer - enzymes convert grain starches to fermentable sugars, and yeast turns those sugars into alcohol and a host of flavour compounds. Brewing, winemaking and distilling yeasts are closely related but selected for different traits. After decades of prioritising efficiency and yield, distillers are increasingly exploring yeast’s role as a driver of aroma and character.The Long Read

Published August 26, 2025

Contents

- What Distillers Want From Yeast

- Wild vs. Cultured Yeast

- From Carlsberg to the M-Strain

- Experimentation: Yeast as a Flavour Lever

- Yeast Beyond Scotland: America & Japan

- How Yeast Shapes Flavour

- Bacteria: Friends, Foes… and Terroir?

- The Course of Fermentation

- How Yeast Is Used in the Distillery

- Geek Appendix: Notable Strains & Supplier Codes

- Glossary

- Further Reading & Sources

Yeasts belong to the phylum Ascomycota, the largest group of fungi. One of its simplest and most useful members is Saccharomyces cerevisiae-the workhorse of brewing, baking and many biotechnological industries from ethanol to enzymes. In whisky, yeast is indispensable: without it there is no alcohol, and without alcohol there is no spirit to distil.

Historically, Scotch whisky producers relied on surplus brewery yeast. This shifted to commercial brewers’ yeast and, eventually, to strains propagated specifically for distilling. For a period many sites mixed brewer’s and distiller’s yeasts; that practice has largely faded, though notable exceptions remain (for example, Ben Nevis uses brewer’s yeast, and Benromach mixes brewer’s and distiller’s strains to add complexity to the wash).

What Distillers Want From Yeast

For decades, the breeding and selection of distilling yeasts has centred on three practical goals:

- Greater carbon dioxide tolerance

- Higher heat tolerance

- Higher alcohol tolerance and yield

As yeast metabolises sugar it generates alcohol, CO₂ and heat-each of which, in excess, will eventually inhibit or kill the cells. High dissolved CO₂ hampers growth, rising alcohol becomes toxic, and elevated temperatures are fatal. Yeast grows fastest near ~38 °C (100 °F) and begins to die around ~48 °C (120 °F), so stainless-steel washbacks are fitted with cooling to keep fermentation in a safe range.

Beyond robustness, distillers value reliable fermentation kinetics (vigorous and complete), good alcohol tolerance (to ~10-12% ABV in the wash), and a temperature profile compatible with their process. While flavour production is paramount in brewing, Scotch whisky has traditionally treated yeast as an engine of efficiency-though that view is changing.

Wild vs. Cultured Yeast

There are two broad categories of yeast used in alcohol production:

Wild (Natural) Yeast

Wild yeasts live on grain and fruit and can trigger spontaneous fermentation. The results are unpredictable: wild microbes arrive alongside bacteria and moulds that may produce sour or off-flavours, and alcohol yields are typically lower. Some brewers (e.g., traditional Belgian producers) still lean on ambient microflora, but the approach is risky for large-scale whisky production.

Cultured Yeast

Breweries and distilleries overwhelmingly use pure, cultured strains. These allow producers to anticipate alcohol yield from known starch/sugar inputs and to tune flavour outcomes more predictably. Within brewing, many houses maintain proprietary strains; selection often favours a clean profile for lagers or fruit-forward notes for ales. Distilling strains typically prioritise reliability and yield, though many can also contribute desirable fruity esters.

From Carlsberg to the M-Strain

Until the late 19th century, breweries pitched yeast from one batch to the next; infections, when they occurred, propagated through successive brews. In the 1880s at Carlsberg in Copenhagen, Emil Christian Hansen isolated and propagated single-strain brewer’s yeast, laying the groundwork for modern pure-culture fermentation.

In Scotch whisky, Distiller’s Yeast (S. cerevisiae) M-strain-often referred to as DCL M-was introduced to distilleries in the early 1950s and dominated from the 1960s through the 1980s. Many distilleries supplemented it with ale brewer’s or baker’s (Mauri) yeast to tweak congeners-often aiming for more sulphury notes and fewer fruity esters. Over time, newer single-strain yeasts offering faster, higher-yield fermentations displaced mixed-yeast regimes. Today, an improved MX variant (commercially Kerry MX) keeps the spirit of M while delivering quicker, more efficient ferments; Kerry M remains a common baseline option.

Yeast Formats

Until the early 1980s, distillers primarily pitched pressed (cake) or dried yeast. In 1983, cream yeast (17-23% solids) gained traction, enabling delivery by tank truck and automated dosing-especially attractive to larger plants. Malt distilleries traditionally used pressed yeast but increasingly employ cream; grain distillers have largely standardised on cream. This handover was part of the reason that Lomond stills fell by the wayside.

Experimentation: Yeast as a Flavour Lever

A wave of new distilleries has embraced yeast trials to differentiate their spirit. Examples include multi-strain regimes combining brewer’s, wine and distilling yeasts; day-by-day rotations blended into the week’s spirit; and side-by-side trials of Mauri, Kerry M and Kerry MX strains. Reported outcomes range from apple-and-pear forward washes to drier, smokier profiles or cleaner, creamy notes. Blends (e.g., MX + Mauri) often show increased complexity.

“There are hundreds of commercially available yeasts and, while not all are suitable for whisky distillation, many can create unique and distinctive flavours in the new make spirit. Until recently, efficiency has tended to dominate the conversation about yeast. However, we’ve already seen a few companies conducting experiments with some wonderful results reaching the market. However, Scotland still lags behind the US in terms of innovation in this area. We have now reached the halfway point in our two-year research and development programme, in which we are experimenting with a wide range of yeasts and fermentations, drawing ideas from different sectors of the drinks industry. We want to find new flavours and styles that we can draw through to our distillate. There are a huge number of variables to consider such as how long you ferment for and at what temperature, but we firmly believe that this research will be beneficial for the industry as a whole.”

- Ian Stirling, co-founder, Port of Leith Distillery

Wild Yeast in Scotch

Glenmorangie Allta-named from the Scots Gaelic for “wild”-was a landmark release, produced using a wild Saccharomyces strain discovered on local Cadboll barley. The strain was isolated and propagated in the lab (rather than relying on uncontrolled spontaneous fermentation) to achieve commercial pitching rates.

Yeast Beyond Scotland: America & Japan

In the United States, many producers maintain house strains tailored to brand style. Four Roses, for instance, is famed for five yeast strains paired with two mash bills, yielding ten bourbon recipes. The yeast codes and broad flavour cues are:

- V - delicate fruit

- K - light spice

- O - rich fruit

- Q - floral

- F - herbal

Japanese producers also exercise tight control; several maintain proprietary strains cultivated and refined in-house.

How Yeast Shapes Flavour

When sugar is metabolised, yeast produces not only ethanol but also esters, aldehydes, organic acids and higher alcohols-all in strain- and process-dependent proportions.

Fermentation-Derived Notes

During fermentation, esters (sources of fruity, tangy character) form-imparting apple, pear, apricot, banana and pineapple notes. Fermentation length matters: shorter runs (~48-50 h) emphasise cereal/malty notes; longer runs allow acidity to rise and ester formation to increase, generally yielding fruitier washes.

Maturation Interplay

Additional aroma compounds arise during cask maturation through both additive and reductive processes. Choices made at fermentation (yeast type, temperature, duration) set up congeners that wood will later transform, tilt or showcase. Blending brewer’s and distiller’s yeasts, or different sub-strains, broadens the palette of precursors available for maturation to sculpt. (See our primer on additive and reductive maturation.)

Bacteria: Friends, Foes… and Terroir?

Whisky fermentations, conducted without a wort-boiling step, inevitably host lactic acid bacteria (LAB) alongside yeast. Controlled bacterial activity can be beneficial: LAB and related genera produce lactic and acetic acids that may be esterified into compounds like ethyl lactate and ethyl acetate (sweet, creamy, fruity, pineapple-like). Certain LAB also contribute γ-dodecalactone, associated with sweet, fatty notes in spirit.

Because malt whisky wort isn’t boiled, active malt enzymes continue hydrolysing starch during yeast fermentation. Bacteria can enter with grain, air or-famously-from the wood of washbacks, whose crevices harbour resident microflora. Many distilleries value wooden washbacks for this reason, while others adopt stainless steel and automated CIP to maximise yield and consistency. (Read more about washbacks.)

Additive & Inhibitory Effects

LAB can metabolise pentose sugars the yeast cannot, slightly increasing potential yield and altering flavour. Yeast prefers mildly acidic conditions (pH ~5.0-5.2) and will function across ~pH 3.5-6.0; LAB thrive near pH 4-5 and tolerate up to ~12% ABV. Some species, notably Lactobacillus brevis and L. fermentum, can push sulphury/meaty notes or depress pH enough to stall yeast-hurting alcohol yield.

Acrolein and Process Choices

LAB also metabolise glycerol to acrolein, a pungent compound undesirable in beer and vinegar production (hence brewers’ preference for stainless steel and rigorous sanitation). Distillers rely on distillation and maturation to reduce or transform such compounds; in some long-aged whiskies, low-level acrolein has been linked to peppery notes.

Local Microbiomes

Studies suggest site-specific LAB communities across distilleries, hinting at a microbiological facet of terroir. Work at Heriot-Watt University’s International Centre for Brewing and Distilling, sampling over twenty distilleries, found distinct bacterial combinations and concentrations-and even identified a new species, Lactobacillus ferintoshensis.

The Course of Fermentation

Fermentation proceeds through three classic phases:

- Lag phase - After pitching into cooled wort (~20 °C), yeast adapts, synthesising enzymes and consuming dissolved oxygen. Glucose is metabolised first; small amounts of ethanol and aroma compounds appear.

- Log (exponential) phase - Cell division accelerates, sugars are consumed in order of size (glucose → maltose → maltotriose). Higher alcohols (fusel oils) form; with available acids they can be converted to esters.

- Stationary phase - Nutrients wane and alcohol rises; growth ceases, and cell death outpaces birth. Lysing cells release enzymes, amino acids and fatty acids that further shape aroma.

How Yeast Is Used in the Distillery

At mashing’s end, wort is cooled to ~20 °C and transferred to washbacks (traditionally Oregon pine or larch; increasingly stainless steel). When the vessel is roughly two-thirds full, yeast is pitched. Agitation and cooling coils manage temperature as it rises from ~20 °C toward ~35 °C during active fermentation. Most malt distilleries ferment for 40-60 hours, producing a wash of roughly 6-8% ABV. The wash rests in wash chargers before distillation.

As an illustrative dose, one large washback might take ~180 kg of pitched yeast (e.g., nine 20 kg bags of Mauri yeast) for ~65,000 L of wort-though actual rates vary by yeast form, strain and plant design.

Industrial-scale pure-culture yeast production expanded in the late 1960s, and today distillers can select from a spectrum ranging from classic distilling strains to brewer’s/wine strains chosen for aromatic nuance.

Geek Appendix: Notable Strains & Supplier Codes

- DCL M (M-strain) - Classic Scottish distilling strain of S. cerevisiae; robust, reliable; balanced ester profile.

- Kerry M - Distillers’ strain commonly used in malt/grain; often yields clean spirit with fruit (apple/pear) depending on wort/fermentation.

- Kerry MX - “Super-strain” descendant of M; faster kinetics and higher yield; can present brighter fruit esters in some setups.

- Mauri (baker’s/ale lineages) - Used alone or as a co-pitch to steer sulphury precursors or creamier mouthfeel; frequently part of trials.

- Brewer’s ale strains (various) - Top-fermenting S. cerevisiae selected for flavour; higher ester production (e.g., isoamyl acetate, ethyl hexanoate).

- Four Roses yeast codes (U.S.) - V (delicate fruit), K (light spice), O (rich fruit), Q (floral), F (herbal) paired with two mash bills to create 10 recipes.

- Hybrid context (beer) - Saccharomyces pastorianus (lager yeast) is an interspecies hybrid of S. cerevisiae × S. eubayanus; noted here for comparison.

Glossary

Washback - Fermentation vessel for wort/wash.

Wash - The beer-like liquid (~6-8% ABV) that is distilled.

Pitching - Adding yeast to wort.

CIP - Clean-in-place; automated sanitising of vessels and lines.

Congeners - Flavour compounds (esters, higher alcohols, acids, aldehydes, etc.).

Further Reading & Sources

- A sip of history: ancient Egyptian beer

- The history of beer yeast

- Lactic acid bacteria (Microbiology Today)

- Characterization of lactobacilli from Scotch malt whisky distilleries and description of Lactobacillus ferintoshensis

- Origins of Flavour in Whiskies and Revised Flavour Wheel: Review

- The ideal distiller’s yeast? (Walker, 2011)

- The microbial ecology of a rum production process

- Life with 6000 Genes