Whisky corks & closures

Published June 26, 2022

Contents

In order to be able to reliably store liquids in bottles, they require a tight seal. Over the decades, whiskey bottles have used spring caps, screw caps and corks. The latter being most commonly used today, while these are typically made of cut, or pressed cork, they can also be made of glass or plastic. Each have their respective advantages and disadvantages. This article however is primarily focused on the cork.

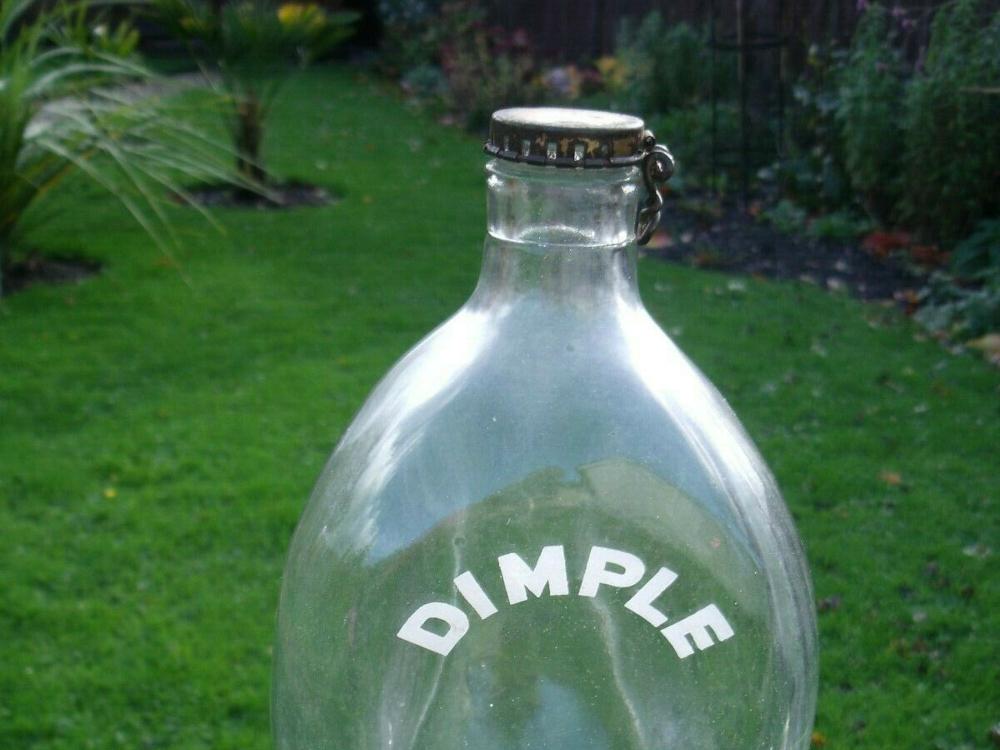

Spring caps

Wire closures, more commonly known as tin cap or spring cap, were used to seal many bottles up until the 1960s. While it’s still possible to find these on the secondary market today the majority are now sealed with screw caps or corks.

This type of closure has several advantages, it is very cheap, stays tight for decades. The only disadvantage is that these are not always easy to open. While these were viewed as somewhat cheaper this was not an issue as bottles prior to the ’60s were almost exclusively blends.

Screw caps

Although invented in 1899 the screw cap was not used widely until the 1970s*. While these were far easier to use and cheaper than corks they still lack the elegance & romance of the premium category whisky enjoys today. For this reason they are now largely limited to blends.

*The screw cap was introduced in 1926 by White Horse Distillers however it widespread use did not take off.

The major disadvantage of screw caps is their longevity, or the occasional lack of it. In most cases, there is a plate made of flexible plastic on the inside of a screw cap, which is intended to seal the transition from the cap to the glass of the bottle. Unfortunately, high proof alcohol interacts with the plastic. If whiskey is in contact with the plastic over a long period of time, it slowly decomposes, the bottle seal will break allowing the slow exchange of air between the bottle contents. As a result of this oxidation and the off-flavors that the plastic gives off, the taste of the whiskey may change over the years.

Cork closures

A cork, as the name suggests, is typically made of cork, though glass and plastic varieties exist. Cork is made from the bark of Quercus suber, more commonly called the cork oak. There are two types of cork:

- Natural cork cut directly from the bark

- Pressed cork - a granulate of cork pieces and glue or resin bonded under high pressure

When the cork is inserted, it is pressed into the bottle at high speed. Since the cork was compressed before corking with a smaller diameter than the bottle neck, the cork can then expand and seal the bottle watertight and gas-tight. Cork is a natural product and is obtained from the bark of cork tree, which grow almost exclusively in southern Europe.

A cork whisky cap doesn’t sit as tightly as a cork in a wine bottle. It’s nowhere nearly as common to empty a bottle of whiskey in a single evening, no matter how great the company. Therefore the whiskey cork has to be a bit looser to be able to close the bottle again at the end of the evening.

Pros and cons of cork

Tha cork is a renewable resource is an advantage of this closure method. Natural corks are also considered to be particularly durable. So why corks became popular so late is a good question. The cork represent a good alternative to spring and screw closures: easy to use and relatively safe & secure.

Unfortunately, the disadvantages of natural cork often outweigh the advantages, which is why alternative closures are increasingly being used. Disadvantages of natural cork are:

- the high cost of natural corks

- that cork loses its elasticity and shrinks over the years

- TCA or cork taint which can impart the taste of cardboard

A common cork issue experienced by whisky fans is that dried cork will break and drop fragments into the bottle. Wine should be stored lying down to keep the cork moist and oxygen away from the wine. However, whiskey contains significantly more alcohol than wine and this high alcohol content combined with the liquid impairs the cork’s functionality and stability under prolonged contact. If whisky is stored incorrectly even minor damage to the cork can result in the whiskey changing noticeably over the years.

Plastic corks

Plastic corks have been around since the early 1990s. At that time, the alternative to natural corks became popular. To counteract the TCA (corked) taste, they were synthesized from a rubber or Teflon mixture. There are currently three manufacturing processes in use:

- Injection molding process: In the injection molding process, the stoppers are cast individually from plastic granules and are usually hard, very smooth and inflexible.

- Extrusion process: This creates a viscous, foamed plastic mass, which is pressed through a nozzle and the plugs are cut off the strand formed.

- Coextrusion: In this process, a homogeneous, foamed plastic mass is introduced into a plastic tube. In this case, the tube provides the radial elasticity of the closure, making this type of process the most suitable in terms of flexibility, sealing and uniformity.

Glass corks & stoppers

Glass stoppers were used as early as the 17th century and had to be ground and tied specifically for the bottle. However these were simply too expensive for widespread use. Since the 2000s glass caps have been successfully produced by some companies. The Vinolok company is one of the best-known manufacturers. These closures are comparable to natural cork from a point of production though they have not as yet found popular acceptance.

Previous

Next