TLDR

Continuous distillation

Unlike batch (pot) distillation, continuous columns feed wash and remove fractions simultaneously. By tuning reflux and plate count you “dial in” purity and congeners - why columns power grain whisky, most American whiskey beer-still systems, many rums, brandies, and neutral alcohol for vodka and gin.The Long Read

Published August 12, 2025

Contents

- What is continuous distillation?

- Anatomy at a glance

- How a column is tuned (the control levers)

- Pot vs column (quick comparison)

- Where columns show up (by spirit)

- Step-by-step: a two-column whisky setup

- Flavour outcomes from a column (rules of thumb)

- Common column designs you’ll encounter

- Pros and trade-offs

- Misconceptions to retire

- See also

- Key takeaways

Columns are the workhorses of modern spirits: fast, steady, and tunable. While pot stills craft character in batches, continuous distillation separates components in a steady state, giving producers precise control of purity and flavour all day, every day.

New to the basics of making whisky? See our overview of the Whisky Production Process.

What is continuous distillation?

Continuous distillation feeds fermented wash/beer into a heated column while vapour rises and liquid flows downward. On each tray (or within packing), rising vapour and falling liquid repeatedly exchange components. Lighter volatiles (ethanol, light esters) enrich as they climb; heavier ones (water, fusels) enrich as they descend. Product is drawn off at controlled strengths while spent liquid leaves the base. Because feed and take-off are continuous, plants run stably for days.

If you want the origin story, start with the 19th-century Coffey (patent) still, which made high-throughput grain whisky possible. See: What is a Coffey still?

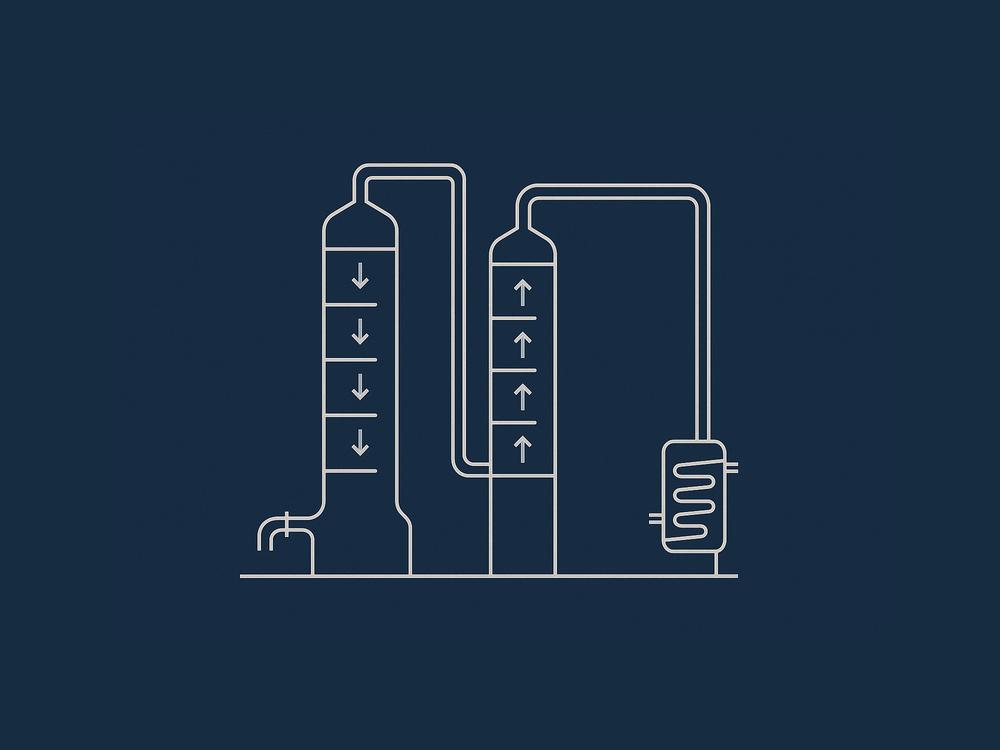

Anatomy at a glance

Most beverage setups use either one tall column with zones or two columns in series:

- Analyzer / Stripper - Steam (or reboiler vapour) strips alcohol from beer descending the trays.

- Rectifier - Redistils the alcoholic vapour; a reflux condenser returns part of the condensate back down the column to sharpen separation.

- Plates or packing - Dozens of equilibrium stages provide repeated condense/re-vaporise cycles (more stages = higher achievable purity).

- Dephlegmator / partial condenser - Controls how much vapour is returned as reflux at the top.

- Product take-offs - Draw points at specific heights for heads, heart, or fusel streams.

- Condenser - Knocks down the final vapour to liquid spirit.

- Steam input / reboiler - Supplies the heat that drives separation.

How a column is tuned (the control levers)

- Reflux ratio: the portion of condensed liquid returned to the column. More reflux → higher purity, lighter style; less reflux → more congeners, heavier style.

- Plate count / effective stages: more stages allow higher ABV at a given reflux.

- Feed composition & preheat: higher beer strength reduces steam demand; preheating recovers energy.

- Take-off rate: pulling product faster lowers purity; slower stabilises and cleans up the cut.

- Copper contact: copper trays/liners scrub sulphury notes; stainless systems rely more on packing choices and residence time.

- Operating pressure: slight vacuum lowers boiling points (handy for delicate aromas in some brandy and rum columns).

Pot vs column (quick comparison)

- Operation: batch (pots) vs steady state (columns).

- Style: pots tend to carry more heavy congeners; columns can be set anywhere from flavourful to nearly neutral.

- Throughput & energy: columns win on efficiency and heat recovery.

- Consistency: columns hold a target ABV and congener window for long runs.

For a deeper dive on pots, see: Pot stills.

Where columns show up (by spirit)

Scotch & other whiskies

- Grain whisky (Scotland) is made on continuous stills (Coffey/multi-column). By law it must be distilled below ~94.8% ABV so some whisky character remains; it’s the backbone of blends and increasingly bottled as single grain.

- Malt whisky (Scotland) remains a pot-still domain, but columns occasionally support utilities (e.g., making neutral spirit for gin lines at the same site).

Ireland - adoption and historic rejection

19th-century Ireland’s large Dublin houses championed rich (single) pot still whiskey and famously rejected the Coffey still, arguing its spirit was too neutral and lacked whiskey character. Scotland embraced Coffey columns for grain whisky, scaling blends globally, while Irish industry declined for many reasons (tax, trade, wars, consolidation) - the Coffey debate became part of that story.

Modern Ireland uses both: Single Pot Still and many single malts remain pot-distilled, while columns produce grain whiskey for blends and neutral for Irish gin/vodka. Explore producers here: Whisky Distilleries of Ireland.

United States

Most major bourbon/rye plants use a beer (column) still followed by a doubler or thumper (a small pot-style re-distillation) to polish the spirit. By law, bourbon/rye must be distilled ≤ 80% ABV (160 proof) and entered into cask ≤ 62.5% ABV (125 proof), so columns are tuned for flavourful, sub-neutral strengths. Craft distillers sometimes use pure pot stills; American single malt often mirrors Scottish practice.

Rum

Everything from feather-light to funk-rich is possible:

- Multi-column “Spanish-style” rums often run at very high rectification for a light, clean profile.

- Agricole/creole columns (e.g., Martinique) run mid-strength to retain grassy, cane-juice aromas.

- Many producers blend column and pot components for balance.

Brandy & fruit spirits

- Cognac mandates pot stills;

- Armagnac traditionally uses a single-column Armagnacais still that delivers aromatic spirit (~52-72% ABV) in one pass;

- Various fruit brandies use petite columns under gentle conditions to keep delicate esters.

Neutral alcohol, vodka & gin

Neutral grain spirit for vodka and the gin base is produced on multi-column plants at 95-96% ABV (near the ethanol-water azeotrope). Gin is then re-distilled with botanicals (or vapour-infused) to the chosen style.

Step-by-step: a two-column whisky setup

- Beer feed enters the analyzer high up; steam rises from below.

- Alcohol is stripped into vapour; spent beer (stillage) leaves the base.

- Alcoholic vapour enters the rectifier.

- The top condenser returns part of the condensate as reflux; you set take-off to the target ABV.

- Heads and fusel oil side-streams can be bled off; hearts become spirit.

- The system holds at steady state until shutdown, cleaning, or a recipe change.

Flavour outcomes from a column (rules of thumb)

- Higher ABV (more reflux / plates) → cleaner, lighter, more citrus/flower; fewer waxes and heavier oils.

- Lower ABV (fewer stages / harder draw-off) → more body, cereal, esters, and sometimes solventy edges if heads aren’t well managed.

- Copper everywhere → brighter fruit, less sulphur; stainless & worm condensers → weightier/meatier notes.

Common column designs you’ll encounter

- Coffey (two-column): analyzer + rectifier; classic for grain whisky.

- Beer-still + doubler/thumper: the American whiskey staple (column + small pot re-run).

- Multi-pressure/multi-column: industrial neutral spirit/vodka plants optimised for energy recovery, heads/tails management, and 95-96% ABV.

- Creole/Armagnacais: narrow, low-pressure columns intended to preserve aroma at moderate strengths.

Pros and trade-offs

Why producers choose columns

- High throughput and excellent energy efficiency (easy heat recovery)

- Rock-steady ABV and flavour windows over long shifts

- Tunability across a wide purity range, from flavourful to near-neutral

Trade-offs

- Less “batch theatre”; flavour changes via set-points, not hand-cut moments

- Risk of over-rectification if pushed too clean for a given category

- More instrumentation and cleaning-in-place to keep running well

Misconceptions to retire

- “Columns only make neutral.”

False. With modest reflux and limited stages, columns can make robust, flavourful spirits. - “Pot spirit is always heavier.”

Often, not always. Tall pots with upward lyne arms and shell-and-tube condensers can be very light; short columns can be tuned heavy. - “Coffey spirit isn’t real whisky.”

Depends on the law. In the EU/UK, whisky from columns must stay below ~94.8% ABV to retain character; within that, it’s categorically whisky.

See also

Key takeaways

- Continuous distillation separates in steady state using plates, packing and reflux.

- By tuning reflux ratio, stage count, and take-off, you set both ABV and congener profile.

- It underpins grain whisky, most American whiskey beer-still systems, a wide span of rums, Armagnac-style brandies, and neutral alcohol for vodka and gin - while pot stills remain central to Scotch malt and Ireland’s Single Pot Still traditions.